Inventory Management Programs

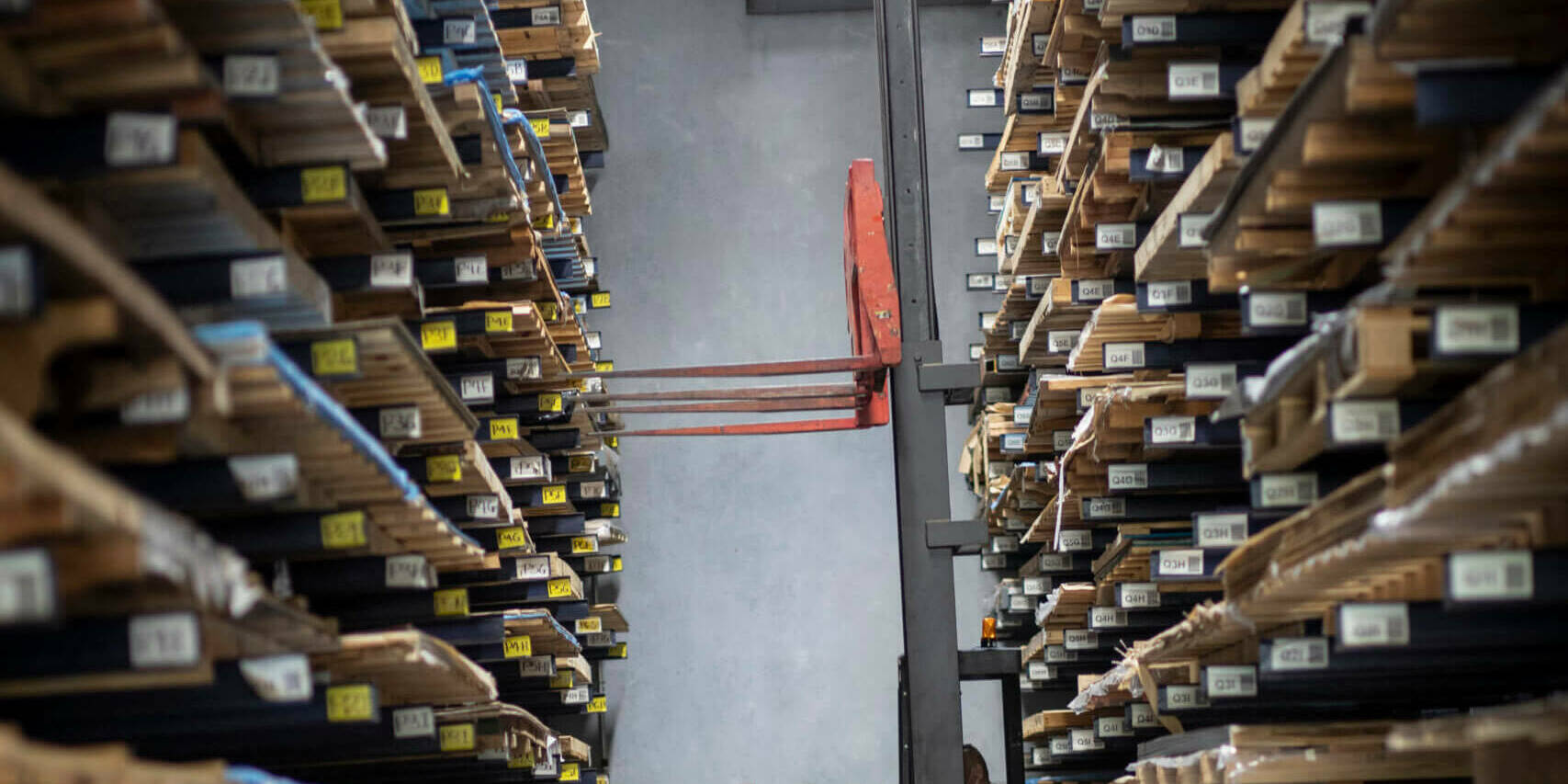

To Aircraft MRO service providers, hours make the difference between making a deadline and falling behind. That’s why they cannot wait for the delivery of items that are commonly used and easily identifiable. The urgency of metal availability requires MRO service providers to hold significant inventories of raw materials which increase their operating costs. Future Metals has partnered with customers to provide a inventory management programs that reduce cost while preserving their ability to provide faster turnaround time with reduced inventories.

A Large MRO service provider in China with steady usage history for material such as Aluminum, Stainless, and Titanium sheet, scalloped seat track, and extrusions, held a vast inventory for AOG emergencies. This inventory was a burden on cash flow but the alternative was to wait for incoming materials which would thus increase turnaround time. They teamed up with Future Metals to establish an inventory management program, which allowed them to minimize inventory on hand as well as free up cash flow until the material was consumed. This organization has since reduced the raw materials inventory carrying cost while preserving their ability to fill immediate needs for materials ensuring on time deliveries.